A Hot Chuck Designed for Your Probe Station

Product Documentation: micromanipulator-h1000-thermal-chuck-systems

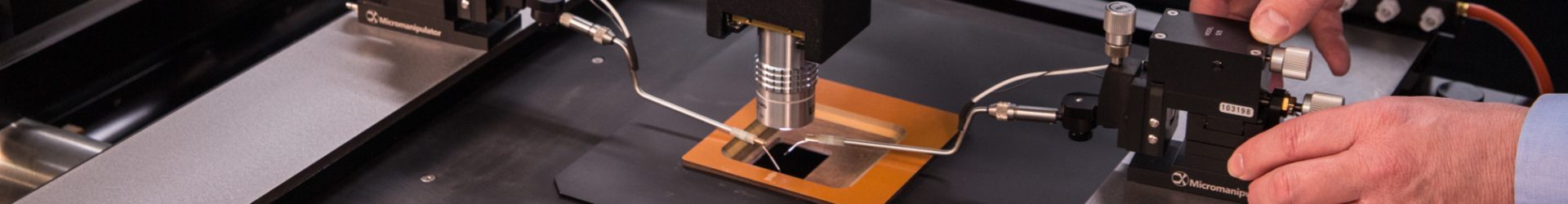

At Micromanipulator we pioneered the integration of hot chuck systems with probe stations. Today we continue to lead the industry with the broadest available temperature range and the most advanced, non-operator dependent performance available on the market for both wafer level, and board level temperature testing solutions. Our exclusive H1000 series thermal chuck offers customers the best planarity, lowest noise, and lowest cost of ownership while our patent pending 2210-LS offers temperature capabilities at the board and packaged level. With several configurations, you will find it easy to get the right wafer hot chuck or thermal system that meets your probing application and budget needs.

Wafer Hot Chuck and Board/Package Level Thermal Systems – Available with Options

Our innovative wafer hot chuck systems support wafer testing from -65 to 400 degrees C and offer customers a choice of the heating power supply. The AC heating supply is for fast heating when chuck noise in the femtoamp level is not needed, and the DC heating supply allows you to achieve the very lowest level measurements. Any of Micromanipulator’s hot chucks are available to support 150 to 300 mm wafers in coaxial or triaxial configurations.

The hot chucks are also available with a choice of three cooling options. Our C1000 simple heat exchanger (HE) cooling is the economical choice for high (above ambient) testing and provides rapid cool down of the chuck after a heat cycle is finished. The C1000 zero degree option is for testing to zero degrees C Finally our HC1000 high performance cooling system is used to test at temperatures down to -65 degrees C.

Our patent pending board and package level prober, model 2210-LS, offers the worlds first test station capable of stress temperatures from (-)40C to 125C. Frost free and stable, the 2210-LS gives our customers the ability to probe their parts after they have been packaged with zero degradation on probing performance or data integrity, another first from Micromanipulator.

We welcome questions and inquiries into our products and offer a worldwide network of service support engineers that provide “system level” support. For assistance regarding your application, please contact one of our engineers.

As leaders in the field, the Micromanipulator Company invented analytical probing back in 1956. Ever since then, we have reliably delivered the tools and life cycle support the semiconductor industry depends on. Part of our company’s philosophy and what drives our success is an unfaltering commitment to our customers’ satisfaction. Contact us to learn more the several configurations offered for our innovative wafer hot chuck or 2210-LS thermal system.